|

HIGHLIGHT |

|

HIGHLIGHT -

JANUARY, 2016 (World Trade Center Phase II Project, New

York)

Versatile

& Compact Foam Cement Mixing & Pumping Setup - High Mobility

with Good Output |

|

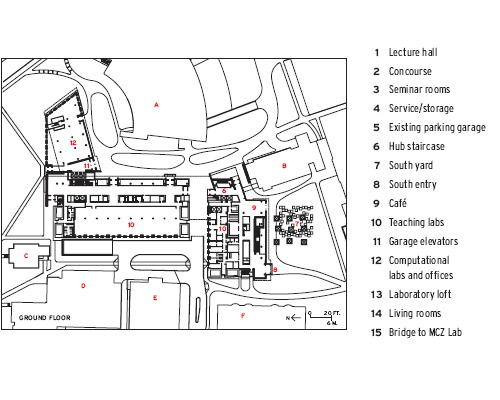

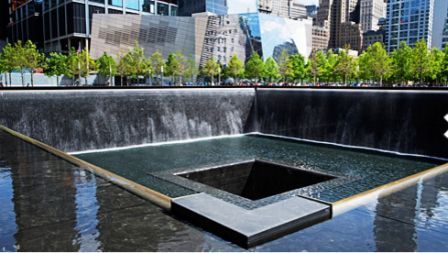

World Trade Center, New York - Phase I (December, 2014) & Phase II

(January, 2016) Geotech Fill Projects |

|

|

|

|

|

9/11 Memorial Museum (upper

view) |

Allied Geotech

Setup - Museum in the back |

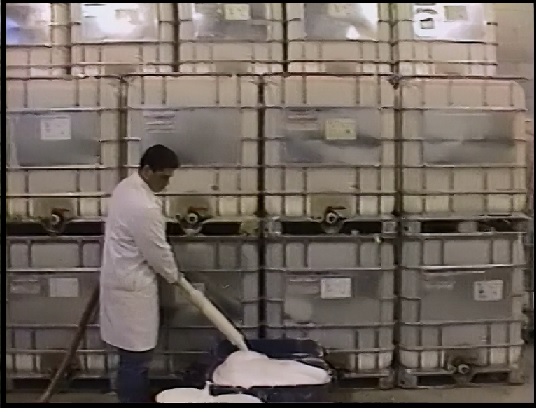

Allied Foam

Liquid Tanks and Foamer Setup |

|

|

|

|

| Two

Mixer/Pumpers on Either Side of Allied Foamer |

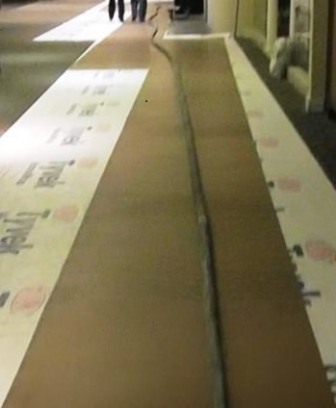

Two Pumping

Hoses Going Down |

Geotech Fill

for WTC Subway Stabilization |

|

Per square foot load

increase can be less than 3 lbs. at 1 inch thickness Per square foot load

increase can be less than 3 lbs. at 1 inch thickness |

Great adhesion to

clean concrete base even without priming Great adhesion to

clean concrete base even without priming |

Unlike the conventional gypsum

based underlayment, Allied foam cement grout is exterior durable

with low water absorption and excellent water resistance. Unlike the conventional gypsum

based underlayment, Allied foam cement grout is exterior durable

with low water absorption and excellent water resistance. |

Controllable slump that

allows ease of slope build-up or screed to level Controllable slump that

allows ease of slope build-up or screed to level |

High tensile strength, good

vibration/crack resistance and

great adhesion to various load-bearing topping materials High tensile strength, good

vibration/crack resistance and

great adhesion to various load-bearing topping materials |

Typical dry densities from

30 - 40 pcf (480 - 650 kg/m3), ideal lightweight grout for fixing

uneven floors. Typical dry densities from

30 - 40 pcf (480 - 650 kg/m3), ideal lightweight grout for fixing

uneven floors. |

Allied foam grout can be

pumped over several hundred feet while still maintains desired

performances Allied foam grout can be

pumped over several hundred feet while still maintains desired

performances |

Much more cost effective

and with significantly better sound and thermal insulations versus

conventional tile grout Much more cost effective

and with significantly better sound and thermal insulations versus

conventional tile grout |

|

|

|

|

| Mixing

& Pumping of High |

Applying of

High Slump Loss |

Finished

Foamed Cement Crown |

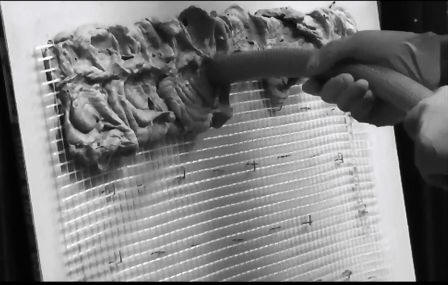

Cross-section

of |

|

Slump Loss Foam Cement |

Foam

Cement on 1 Vertical/4 Horizontal Slope |

On Highly

Sloped Geofoam |

Landscape

after ~ 1 year |

|

HIGHLIGHT - OCTOBER, 2014 |

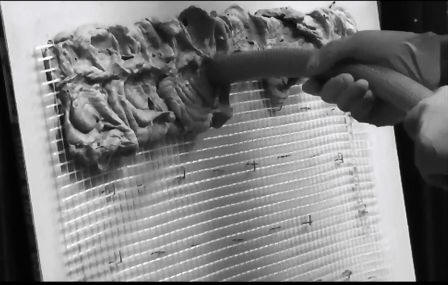

Allied water resistant 9 pcf (145

kg/m3) insulative foam cement - Click here for QuickTime

video

Nov., 2014

Nov., 2014 |

|

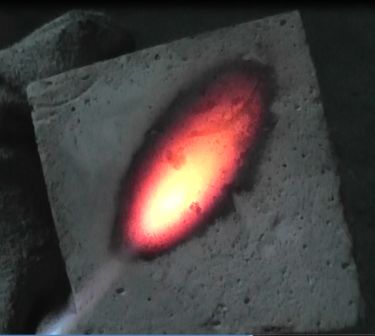

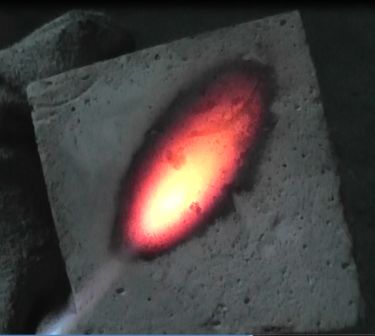

NON-FLAMMABLE & SMOKE-FREE

FOAM CEMENT WITH HIGH INSULATIVE FACTORS |

|

PROVIDING FIRE-SAFE

EXTERIOR & INTERIOR INSULATIONS FOR INDUSTRIAL, COMMERCIAL,

& RESIDENTIAL FACILITIES |

Unlike polyurethane or

polystyrene foams, Allied foam cement at < 8 PCF is

non-flammable, without fire retardant & smoke-free with excellent insulative

factors & ease of application

|

|

|

|

Allied insulative

foam cement - wall cavity fill |

Allied flexible

foam

cement - wall rendering |

8 pcf Allied foam

cement being torched - no smoke, no

fire. |

8 pcf Allied foam cement

after torch removal |

The

6.9 pcf (111 kg/m3) block

(thermal "R" per inch > 3.0 or

> 0.52 m

2.K/(W.inch))

above passed the Cone Calorimeter Test (EN 5660-1) in

ignitability,

combustibility, smoke production, and toxic gas

production

without using fire retardant

(detailed data will be available upon request)

|

|

|

|

|

-

With densities from over 1,450 kg/m3

(90 pcf) to as low as 48 kg/m3 (3 pcf) for

geotechnical engineering

& landscape architecture,

lightweight concrete roof deck,

lightweight wall and floor panels

partitions

lightweight concrete blocks

insulative cinder block inserts.

-

With densities from over 1,450 kg/m3

(90 pcf) to as low as 48 kg/m3 (3 pcf) for

geotechnical engineering

& landscape architecture,

lightweight concrete roof deck,

lightweight wall and floor panels

partitions

lightweight concrete blocks

insulative cinder block inserts.

-

High flexural strength, good Mandrel bending

behavior without cracking, good adhesion, exterior durability and

excellent water resistance.

-

High flexural strength, good Mandrel bending

behavior without cracking, good adhesion, exterior durability and

excellent water resistance.

-

Allied pervious

& non-pervious foamed cement are capable for waste

encapsulation, immobilization, soil stabilization and leachate filtration. Allied

long lasting foam, applied as a surface cover on landfill sites and effluent ponds and lagoons, will effectively suppress

noxious odors, vapors, litter and vectors, avoiding serious environmental issues.

-

Allied pervious

& non-pervious foamed cement are capable for waste

encapsulation, immobilization, soil stabilization and leachate filtration. Allied

long lasting foam, applied as a surface cover on landfill sites and effluent ponds and lagoons, will effectively suppress

noxious odors, vapors, litter and vectors, avoiding serious environmental issues.

-

with densities as low as 23 kg/m3

(1.5 pcf) for fabrication of insulative and high temperature resistant ceramic

foams.

-

with densities as low as 23 kg/m3

(1.5 pcf) for fabrication of insulative and high temperature resistant ceramic

foams.

-

Allied chemically engineered open and closed pore properties

within their cell structure are very similar to that

of urethane and polystyrene foams, but

without their associated poor fire resistance, yet with

outdoor durability and great cost advantage.

Click here

for QuickTime

Nov., 2014

Nov., 2014

-

- with excellent strength and thermal shock resistance for fabrication of durable firebricks

used as high performance insulative materials for kilns and incinerators.

- Flexible

and very light (< 1.5 pcf or 24 kg/m3). Various geopolymer foam

composites can achieve insulative value R > 3.8 per inch and fire

resistance.

- Flexible

and very light (< 1.5 pcf or 24 kg/m3). Various geopolymer foam

composites can achieve insulative value R > 3.8 per inch and fire

resistance.

-

Using a foamable mixture as an expansion agent permits application of a

controlled film thickness with improved resin distribution and penetration

into the fabric fibers. -

Using a foamable mixture as an expansion agent permits application of a

controlled film thickness with improved resin distribution and penetration

into the fabric fibers.

Foam textile binders

dry

quickly without causing fiber distortion.

-

Using adhesives, based on Allied's foam system, will reduce adhesive consumption and

prevent adhesive absorption by porous substrates.

-

Using adhesives, based on Allied's foam system, will reduce adhesive consumption and

prevent adhesive absorption by porous substrates.

-Specially formulated foam from Allied can be used as long

duration fire fighting barriers for the containment of forest fires. -Specially formulated foam from Allied can be used as long

duration fire fighting barriers for the containment of forest fires.

|

|

|

| Our Mission |

| At Allied we are committed to the continuing

development of versatile and highly stable aqueous foam and systems

with a wide range of properties and applications that meet the specific

needs of our customers in the various industrial sectors. |

| Technology |

|

Allied Foam Tech has developed a universal foam technology for a wide range of

industrial and

environmental applications. The excellent stability and dynamic nature

of Allied's

make them ideal for use in

reducing the weight of cement/concrete, ceramics, firebricks,

adhesives, coatings, and binders. Foam stability derived from Allied's

many foam systems usually outranks that of any other existing

technologies available in today’s marketplace. make them ideal for use in

reducing the weight of cement/concrete, ceramics, firebricks,

adhesives, coatings, and binders. Foam stability derived from Allied's

many foam systems usually outranks that of any other existing

technologies available in today’s marketplace.

The

AFT

series of foam agents, using compressed air and Allied foam

generating equipment, generates very fine and stable foams. They are used

for the manufacture of lightweight

(or foamed) concrete, lightweight ceramics, insulative

firebricks, alternative landfill cover, foam coatings, foam adhesives,

long-duration firefighting foams and other uses. Substrates such as

cement, concrete, coating formulations or others that incorporate

Allied's foam products usually exhibit reduced weight with improved

workability, insulation value, sound proofness, and expanded

applications.

Allied

has also developed various models of compact and versatile foam

generating equipment for production or field application

that can be manually or remotely controlled.

|

- Postal address:

- Allied Foam Tech Corp.

- 146 Keystone Drive

- Montgomeryville, Pa 18936, USA

- (For more detailed contact info please see

CONTACT

page)

|