|

|

|

|

|

| Recent News November, 2013 |

|

1. Allied Foam Tech has been awarded by USCA as the best chemical machinery & equipment manufacturer in Montgomeryville, Pennsylvania in 2009-2011 and 2013. |

|

2. October, 2013- Our innovation (click here for details) on "Wood-like Flexible Cementitious Foam" is being considered for the 2014 Edison Award for Material Science. |

|

|

|

|

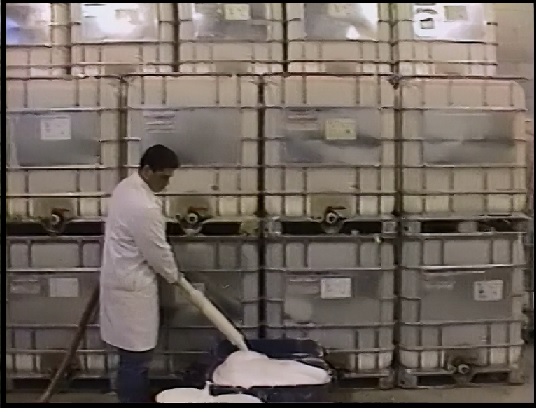

| Chemical Manufacturing | Medium Size AFT-G6 Foamer | Internal Foam Testing | Training Contractors at Field |

|

INSULATIVE GEOPOLYMER FOAM AND FIRE RESISTANT FOAM COATING |

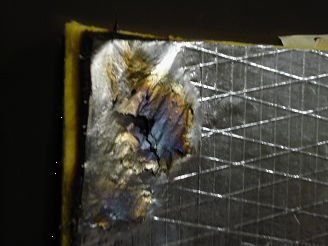

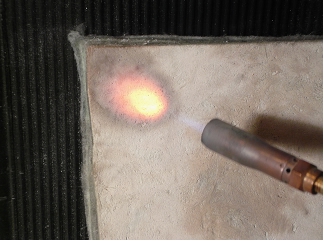

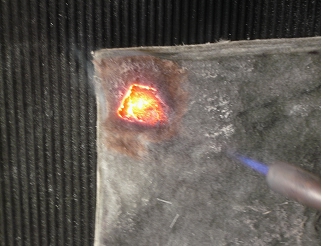

| Ductliner w. Geopolymer Foam Coating | Geopolymer Foam/Ductliner | Foil Covered Ductliner Control | Foil/Ductiler Control |

| Torch Applied | After Torching | Torch Applied | After Torching |

|

|

|

|

|

| Torch Fiberglass Mat w. Allied Geopolymer Foam Coating | Torch Fiberglass Mat w/o Coating (Control) |

|

|

|

Lightweight Ceramics and Firebricks |

| Ceramics based on Allied foams have fine pore size, excellent stability and high integrity. Foam Ceramics can be as light as < 20 pcf ( 323 kg/m3 ) and with use temperatures as high as > 3,000oF (see blocks on left).. A fiber re-enforced foam ceramic crucible under scorching torch is shown on right. |

| High Temperature Foam Ceramics (density < 20pcf) | Texture of Allied's Foamed Ceramics | Texture of Conventional Firebricks | Foam Ceramics (under propane torch) |

|

|

|

|

|

| uniform & fine pores | non-uniform & coarse pores | click for larger view |

|

|

Allied's Foamed Ceramics | Other Firebricks |

|---|---|---|

| Density | Cold Crushing Strength (in psi) | |

| 46-48 pcf | >>500 | 170a,142b 270c,171d |

| 21 pcf | >150 | not available |

| a Published data for Firebrick K26LI (Thermal Ceramics) |

| b Published data for Firebrick A-7 (Korea Refractory) |

| c Published data for Firebrick Z-26 (BNZ Materials) |

| d Published data for Firebrick SIB-140 (Won Jin) |